自上个世纪90年代中期以来,纺织品数码印花的研究变得越来越重要。该应用领域提供了以快速设计时间打印高质量图像的可能性。特别是对时尚行业来说,一个巨大的优势是能够实现从小批量到大批量的按需打印。根据英国WTiN Intelligence:Digital Textiles的分析,全球纺织品数码印花的产量正以每年约20%的速度增长。尽管增长迅速,但到目前为止,使用数字印刷的纺织品生产比例只有3~5%左右。

在纺织品上进行有效的工业数码印花的一个困难因素是——纺织基材五花八门,从天然的(如棉花、羊毛或丝绸)到合成材料(如涤纶和混纺织物)。所有这些织物类型都需要不同类型的墨水,其前后处理和加工过程也有额外的不同要求。主要在工业中应用的墨水类型是用于天然纤维的活性墨水和用于涤纶数码印花的升华/分散墨水。

颜料墨水:特性、应用和市场

水基颜料墨水不是可溶性染料,而是使用不溶性颜料来给纺织品着色。与染料相比,这些颜料对特殊纤维不具有真正的亲合力,这使得它们既适合用于各种纤维的最上层着色,也适用于混纺织物。

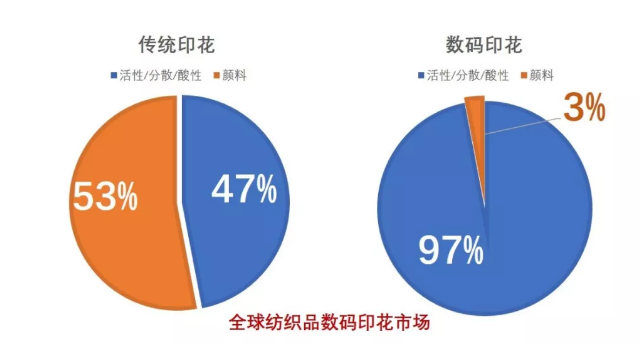

然而,全球纺织品印花市场显示,颜料墨水只占纺织品数码印花墨水的3%左右。最常用的墨水仍以活性染料、分散染料和酸性染料为主。目前颜料墨水在纺织品数码印花市场中所占的份额较低,原因有很多。

像在前面提到的那样,由于在织物表面进行印花时,使用了粘合剂来提高颜料墨水在基材上的附着力,因此大多数颜料墨水在反复洗涤和耐摩擦牢度方面都受到了限制。此外,织物的手感往往比活性印花更硬,这是主要问题之一,尤其是应用在时装或床上用品中时。

另一方面,颜料墨水的使用显示出了一些显著的优点。由于适用于在各种纺织品基材上打印,颜料墨水可以提供广泛的应用范围,包括家用纺织品、软标牌、横幅、时装(主要是t恤)或专业产品等,都可以使用颜料墨水进行打印。它在需要高耐光牢度的地方也特别有用。并且,与活性印花相比,颜料印花的整个工艺过程非常快速和简单。

颜料印花与活性印花的对比

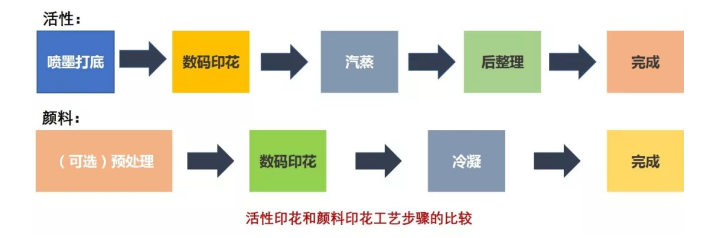

在纺织品数码印花中使用颜料墨水的好处之一是,其工艺过程简单。如下显示了颜料墨水与活性墨水的印花工艺对比。由于活性染料的化学特性,印花后必须粘合到纺织纤维上。因此,需要在102℃(饱和蒸汽)下汽蒸处理8~12分钟。随后,必须在大约50°C至98°C的不同温度范围的复杂洗涤过程中(经过处理)去除未结合的染料,用皂洗剂到60°C,最后是30°C(微酸性)。然后要烘干印花织物。

相比之下,颜料印花工艺不需要复杂的汽蒸和洗涤工序。由于颜料仅印在织物的顶层而没有任何化学成分,因此织物必须在150~170℃下冷凝几分钟以固化颜料。如此一来,由于没有清洗步骤,颜料印花过程所需的水量大大减少。这可能正是决定将来是否使用数码颜料印花的关键因素。

然而,关于颜料墨水的印花工艺还有一点需要指出。由于颜料颗粒的不溶性,它们的沉降可能会导致喷墨打印机的细喷嘴堵塞。所以,要克服这个问题,有两点需要注意:第一,所有的墨水在使用前都必须充分搅拌;第二,带有循环系统的打印头的必要性变得越来越重要。循环系统提供了一种连续的流动性,避免了因沉淀而堵塞喷嘴。特别是,主要基于无机化合物二氧化钛的白色颜料墨水需要那些循环系统。

展望

颜料墨水在纺织品数码印花领域具有广阔的应用前景,特别是在改善环境和简化工艺方面。

除了用于常用的纺织材料如棉、涤纶和锦纶之外,还可以使用颜料墨水在混合织物上轻松打印,例如通常需要使用两种不同类型的墨水进行打印的棉—涤纶混纺织物。

此外,一些墨水制造商正在努力开辟使用颜料墨水在特殊材料上打印的更大可能性,对通常难以或几乎不可能进行数码印花的纺织品基材进行了一些测试,并且这些测试已经取得了令人满意的结果。

最后,纺织品数码印花颜料墨水在特殊材料应用的市场上有很大的机会能抢占一席之地,当需要节约能源和用水量时,也能在常用的纺织纤维上一展身手。

2019-08-28

2019-08-28